InSPECT: first miniature photonics spectrometers for real-time tissue diagnostics tested

Today physicians are still severely hampered by the lack of precision of the needle tip location during a biopsy. Looking at lung cancers, 25% of the diagnoses suffer a false negative outcome through traditional biopsy methods. In the future, this can be avoided: for the first time, the European project InSPECT developed miniature spectrometers with integrated light sources enabling guided sensing. Ground-breaking was the fabrication of the reflective segmented diffractive gratings with VUB B-PHOT’s in-house polymer prototyping pilot line.

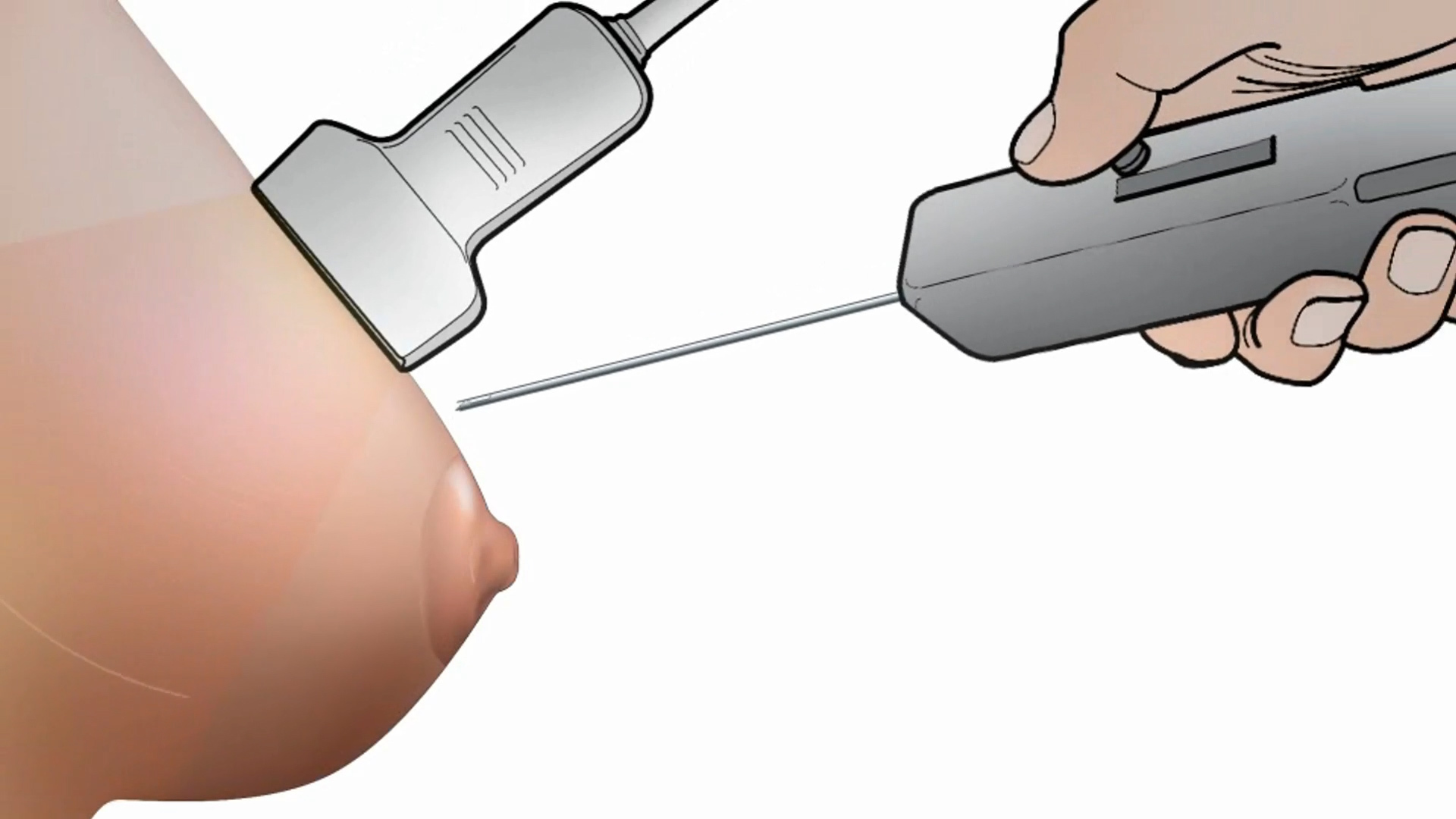

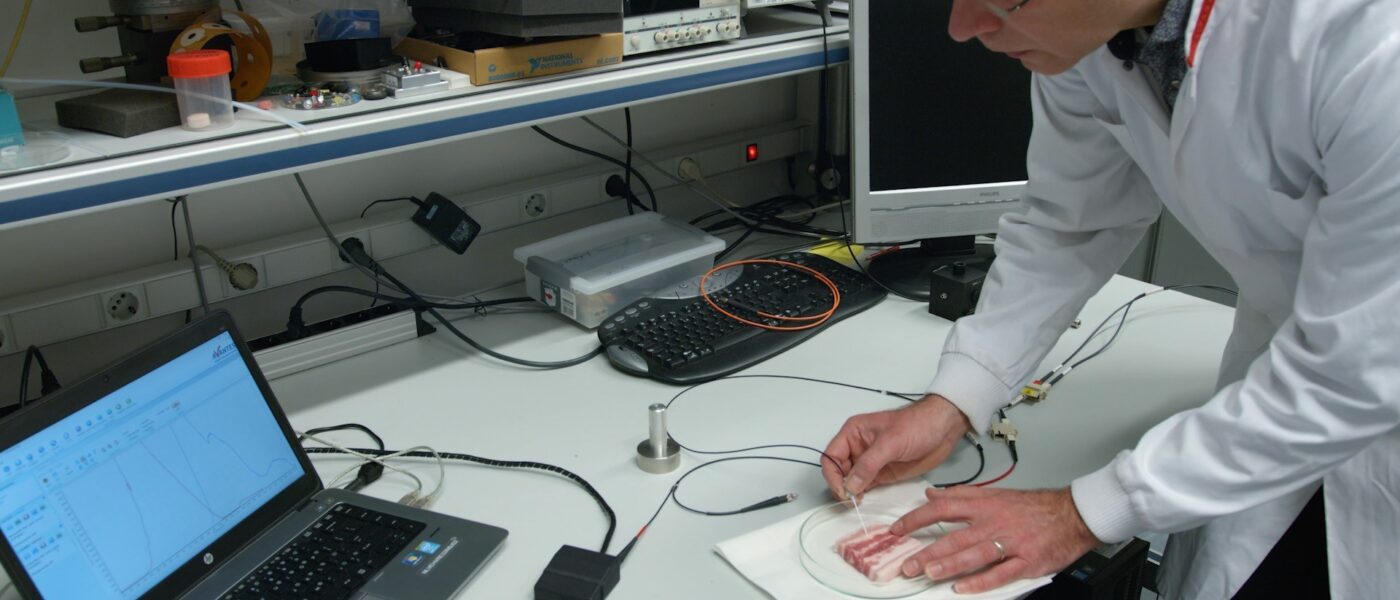

By integrating an optical fiber inside a biopsy needle, cancerous and non-cancerous tissue can be illuminated and differentiated by spectral analysis. Backscattered light is collected and led to a spectrometer that identifies spectral fingerprints like water, fat and hemoglobin. The different concentrations, collected by a second optical fiber, give real-time feedback to the physician during the medical intervention.

This method for tissue detection allows a fast and accurate diagnoses that can significantly accelerate the start of the cancer treatment, vital to increase the survival rate and recovery of each patient.

The photonics spectrometers pave the way for ultimate miniaturization of biophotonic and medical applications.

Prof. dr. Theo Ruers, Professor of Surgical Oncology at the Netherlands Cancer Institute comments: "There is possibility to use those technologies in smart surgical devices so the surgeon knows exactly if he/she is cutting into tumorous or into normal tissue. Another application could be to develop implantable tissue sensors."

The InSPECT video shows the opportunities of improved biopsy guidance technology in oncology.

Miniaturized light sources and spectrometers at full spectrum

The DRS (Diffuse Reflectance Spectroscopy) systems today use a commercial halogen-type light source and two spectrometer devices, one for the visible and near infrared region of the spectrum (using silicon based sensors) and one for the short wave infrared region above 1 um wavelength (using indium-gallium-arsenide sensors).

“The miniaturisation of the broadband spectrometer to a cubic-inch size was a key element in the success of InSPECT," says Prof. Heidi Ottevaere . "VUB B-PHOT designed multiple diffractive gratings on a single wafer, each covering a spectral sub-band of the full wavelength region. At the end of InSPECT the gratings were combined with the two-dimensional silicon and InGaAs optical sensors to obtain a spectral sensor, and was benchmarked to commercial spectrometers."

Within the European Horizon 2020 project InSPECT, two new classes of spectrometer systems have been developed:

1. a compact cubic-inch like broadband spectrometer based on diffractive optics, and

2. a spectrometer system based on Si-based TriPleX waveguide technology integrating the spectrometer onto a photonic integrated circuit.

Further, a new class of broadband light source has been developed based on solid state laser excitation of luminescent materials. For this, new luminescent materials have been developed covering the spectral range from 400 to 1700 nm and a prototype light source incorporating these materials has been realized.

Eliminate delays in diagnose and treatment

Physicians will be able to perform a precise and instant diagnoses, with the compact cubic-inch broadband spectrometers that can be developed at high volume and low-cost.

The new generation of very compact and more cost-effective spectrometry solutions generate viable business models bringing spectral sensing inside the operating theatre, at general practitioners in their consultation rooms and to remote healthcare centers.

VIDEO - Discover how the design and fabrication of optical components and systems can impact healthcare by watching the InSPECT video that shows the opportunities of improved biopsy guidance technology in oncology.

About Inspect

The European-funded H2020 project InSPECT is coordinated by Philips in The Netherlands, bringing together eight partners representing expertise in optics, photonics, device manufacturing, sensors and medical technology: B-PHOT Vrije Universiteit Brussel (Brussels, Belgium), Xenics (Leuven, Belgium), Anteryon (Eindhoven, The Netherlands), Lionix International (Enschede, The Netherlands), Aifotec (Meiningen, Germany), Avantes (Apeldoorn, The Netherlands), and the Fraunhofer Institute for Reliability and Microintegration (Berlin, Germany). The project is funded within the Research and Innovation Action of Horizon2020, and in collaboration with Photonics21. More details can be found at the InSPECT website.